Driveway Water Barrier

FREE SHIPPING

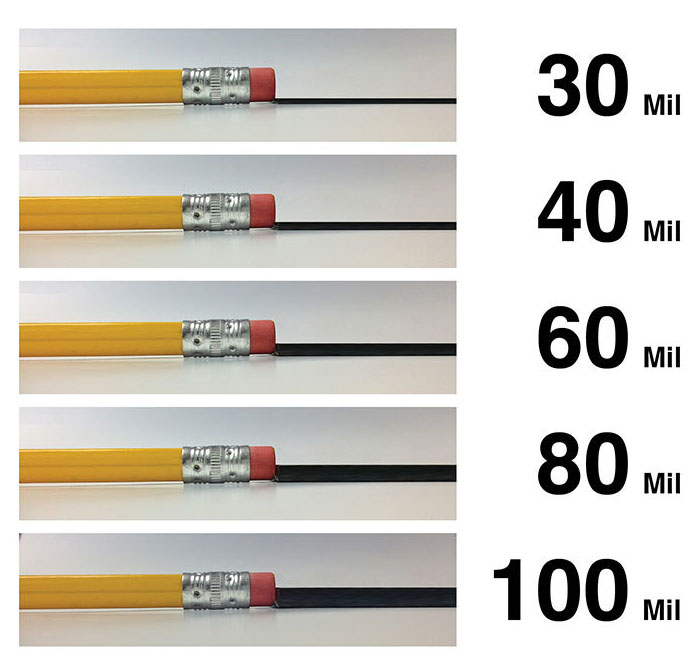

The Driveway Water Barrier, manufactured in the USA, consists of 100% high-density polyethylene (HDPE), known for its strength and durability. This product is available in a variety of sizes and thicknesses to suit diverse needs. Thickness options range from 30 mil to 100 mil, where a mil is one-thousandth of an inch. The barrier comes in roll heights from 18 inches up to 60 inches, with most rolls measuring 100 feet in length, though some are available at 80 feet.

Key Features:

Waterproof and UV Resistant: Engineered to endure outdoor conditions, perfect for driveway applications.

Robust and Durable: The material is non-biodegradable and impervious to damage from insects and rodents. It is also resistant to rot and mildew.

Installation: Rolls can be connected with double-sided HDPE seam tape to create a continuous barrier.

Stocked in Kansas City, MO, this product typically ships within one business day, ensuring prompt delivery for your project needs.

Material Thickness:

30 mil = 1/32”

40 mil = 3/64”

60 mil = 1/16”

80 mil = 5/64”

100 mil = 3/32”