Flower Box Liner Plastic

FREE SHIPPING

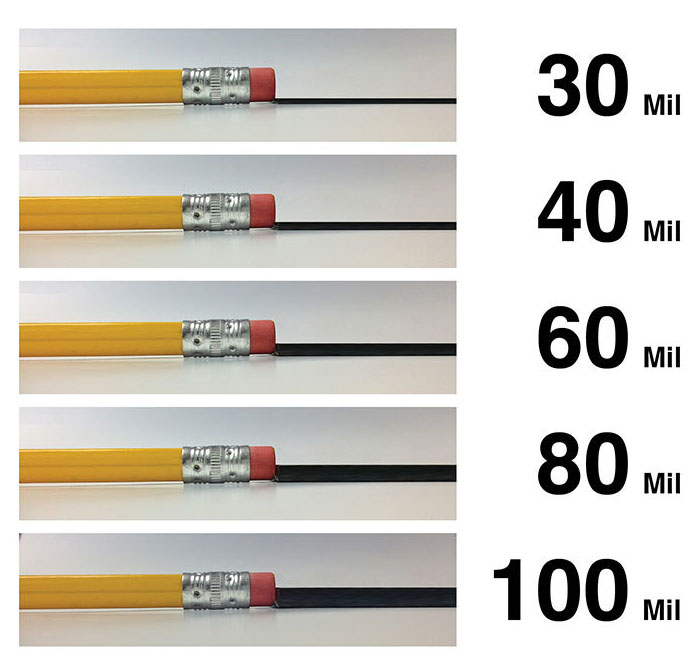

Our Flower Box Liner Plastic is composed of high density polyethylene which provides a smooth, waterproof, and puncture resistant lining for your planter box. This commercial grade plastic can be easily cut with a standard utility knife to fit the planter box dimensions. This product is non-biodegradable and will not rot or mildew. It is available in thickness options ranging from 30 mil to 100 mil and in various depth options.

The Flower box liner plastic is an American made product and has an estimated 100 year material lifespan when not exposed to direct sunlight.

Material Thickness:

30 mil = 1/32”

40 mil = 3/64”

60 mil = 1/16”

80 mil = 5/64”

100 mil = 3/32”