Hard Plastic Sheet for Roofing Applications

FREE SHIPPING

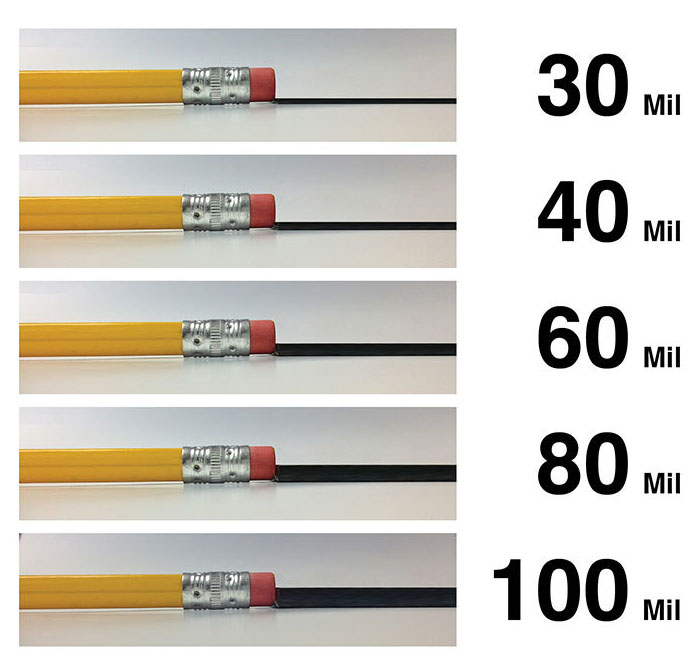

Our HDPE is a hard plastic sheet which can be utilized in a number of different roofing applications. The material is UV resistant, available in both black and white colors and is shipped in various roll sizes ranging from 10” in width to 60” and in various thicknesses. Roll lengths range from 80’ to 100’ depending on the specific roll width and mil thickness. Designed to be both tear and puncture resistant, the plastic is well suited for installation in demanding environments. The material can be installed in both cold and hot climates and is appropriate for both residential and commercial installations. The HDPE roll material is manufactured in the USA and the price listed includes delivery throughout the continental United States.