Rectangular Planter Liner Material

FREE SHIPPING

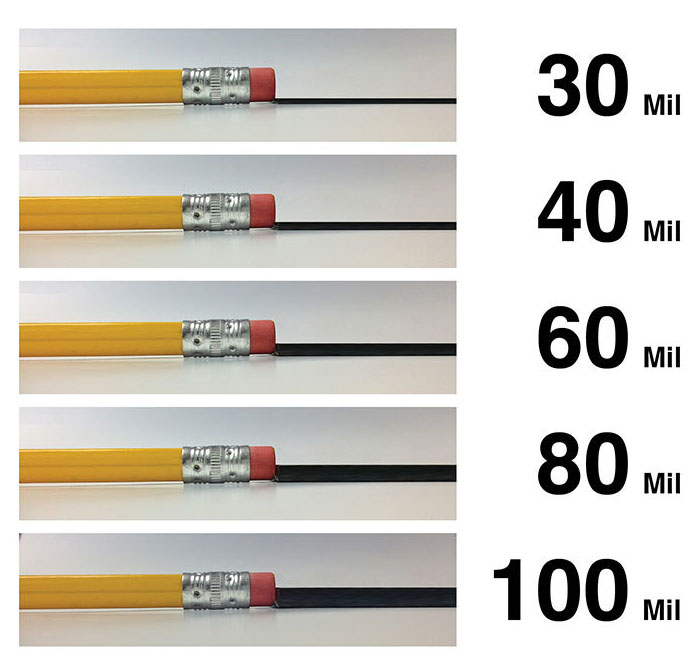

Our Rectangular Planter Liner Material is a HDPE plastic that provides a smooth, puncture resistant, and waterproof liner for your planter box. This product is available in 30 to 100 mil thicknesses and in various depths. It can be used in both hot and cold climates, and can be easily cut with a standard utility knife.

The rectangular planter liner material will not rot or mildew, and is resistant to insect and rodent damage. This product is made in America.

Material Thickness:

30 mil = 1/32”

40 mil = 3/64”

60 mil = 1/16”

80 mil = 5/64”

100 mil = 3/32”