Ultra Thick Plastic Roll - Heavy Duty Sheet Material

FREE SHIPPING

Available in a wide variety of different sizes and thicknesses, our HDPE (high density polyethylene) is ultra heavy duty, tear resistant and durable. With various applications, our HDPE is formulated to last in both hot and cold climates, is UV resistant and provides a projected installed lifespan of greater than 100 years (when installed away from direct sunlight).

Free Shipping on all HDPE Plastic Film Rolls.

Manufactured in the United States.

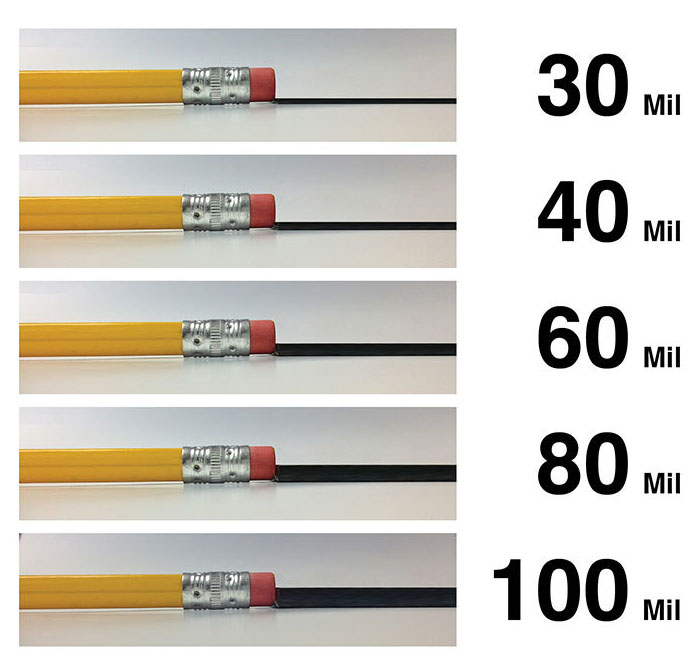

Material Thickness:

30 mil = 1/32”

40 mil = 3/64”

60 mil = 1/16”

80 mil = 5/64”

100 mil = 3/32”